The ruins of ancient civilizations prove the existence of cultures thousands of years gone which nonetheless rival our own in many aspects. Take the Roman Colosseum, as an example. It was but one of many such arenas which stood across the Roman Empire, in varying sizes depending on the local population. As with today, the great stars of the arena, the gladiators, wrestlers, charioteers, and other performers became stars in the hinterlands, as it were, before performing before the Emperor in Rome or Caesarea. Engineers and architects built the arenas, the great cities, and the roads which connected them.

Ancient engineers harnessed sources of motive power to create tools to shape metals and stone, reroute water, and alter the landscape. When the ancient Greeks first encountered the Great Pyramids in Egypt the monuments were already thousands of years old, as were the techniques employed to build them. The Greeks adopted the Egyptian’s techniques, improving on them, and later the Romans advanced the technology of the Greeks. Engineers designed and built public spaces, roads, temples, weapons, and all the sinews of their civilizations. Here are ten ancient engineering methods and accomplishments.

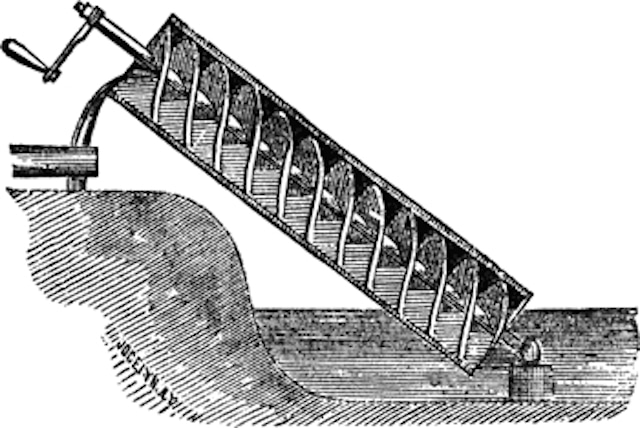

10. Screw pumps for irrigation and mining

The Greek mathematician Archimedes is credited with inventing the screw pump, though evidence suggests he encountered the device in Egypt and improved its design. The Ancient Egyptians used a screw pump which consisted of a cylinder around which spiraled a hollow tube. Another design included a spiral groove in the outside wall of the cylinder, covered with either leather or wood. When rotated in water, the screw pump moved water from the source to another level. Cylinders were rotated by motive power provide by men or draft animals. Archimedes improved the pump by hollowing out the cylinder and inserting a screw within, allowing for the transfer of a greater amount of water, as well as the pumping of grains, sand, and other materials.

The screw pump allowed water to defy the principle that fluids seek their own level. Water, elevated to greater heights, could be used for irrigation, for drinking, for driving waterwheels. It could also be diverted to return downhill, washing away the soil and rock of a hillside through erosion, in an ancient form of hydraulic mining. The Greeks used rotating stones driven by water power to shape metals. They also developed water driven saws used to cut marble and wood, to crush stones, and to sharpen chisels and other tools used by soldiers and builders in their various pursuits. The screw pump remains an important and frequently applied technology in the modern world, used for pumping fluids and gases in diverse applications.

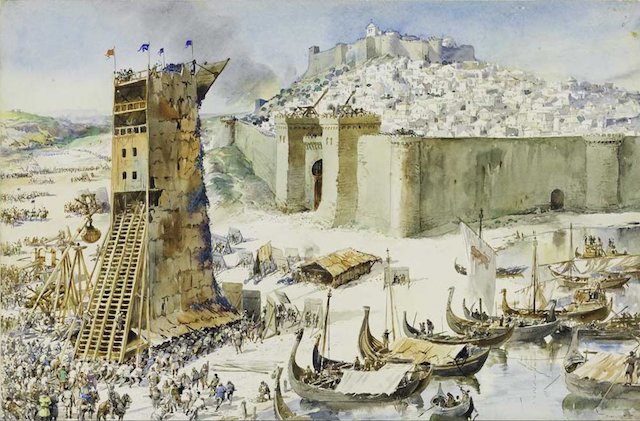

9. Movable siege towers

It’s a sad commentary on the history of humanity that war drives engineering innovation. The ancients applied engineering to the art of war to gain advantage over their enemies. In the ancient world explosives and cannon did not exist, making the seizure of fortified positions and cities a daunting task. Such was the reason most cities surrounded themselves with walls from which a defense could be mounted against attackers. Breaching or surmounting walled positions became a goal of offensive operations in warfare. The ancients developed “siege engines” — tall, unwieldy, and movable towers — which allowed attackers to approach the walls and fire their weapons over them, as well as allowing troops to sally forth.

Usually, engineers with the army built the towers near the site of their eventual use. Made largely of wood, the towers, which could reach the height of several stories, were covered in a non-flammable material, if available. They were propelled by men and draft animals, the former usually slaves or prisoners. Siege engines appeared throughout the ancient world. To counter them, military engineers developed the concept of a floodable ditch surrounding fortified areas, known as a moat. The largest known siege engine of antiquity, the Helepolis (Taker of Cities), suffered defeat at the siege of Rhodes when a moat prevented it from reaching the walls of that city in 305 BCE.

8. Roman concrete

The aggregate commonly referred to today as Roman concrete developed sometime in the 1st century CE. Its durability is one of the reasons so many Roman structures survived over the ages. Though several different mixtures of Roman concrete existed, using gypsum and quicklime as binders, Roman engineers came to favor the use of volcanic ash, called pozzolana (pit sand). Concrete made with the volcanic residue resisted cracking, and unlike even most of today’s modern concretes, was impermeable to damage from salt water. Immersed in salt water, Roman concrete developed a crystallized structure which served as a barrier to penetration. Roman marine concrete, used to build piers and other waterside structures, is considered one of the most durable construction materials ever devised.

Roman concrete contained coarser aggregates than its modern counterpart, making it less fluid than today’s version. Building’s erected from it were usually faced using tiles, frescoes, bricks, or stuccoes. The concrete’s superior strength allowed for innovative uses, including the domed roof, which provided for buildings with far more open interior spaces due to the use of fewer support columns within. Roman engineers continued to experiment with and improve their various mixtures of concrete over the centuries, eventually creating a marine mixture which has lasted 2,000 years with little sign of wear. Today, numerous construction companies and communities in North America and Europe are studying the use of ancient Roman concrete mixtures. They are less expensive to manufacture, have a lower carbon footprint, and are demonstrably more durable.

7. Roman hydraulic mining

Roman mining engineers used a combination of hydraulic power and fire to develop surface mines for ores. The water needed for the mines usually came to the site in an aqueduct, from which the miners directed it at the face of the rock. To create pressure, gravity was exploited by raising the water delivered via the aqueduct through the use of a waterwheel, driven by slaves or animals. Screw pumps also were applied in some cases. Before directing the partially pressurized flow of the water against the face of the rock, the rock was heated by building large fires against its face. The heat weakened the rock by expanding cracks, which then broke apart when hit by the water.

Ore thus extracted was also subjected to water, a method known as hushing. Roman hydraulic mines were thus large and bustling commercial centers, several with multiple water raising machines, requiring large pens for livestock and shelter for slaves. Remains of several Roman hydraulic mines are scattered across the lands which once formed the Roman Empire, from Las Medulas in modern Spain to the ruins of Dolaucothi in the Cambrian Mountains of Wales. The latter used aqueducts to transport water from the nearby Cothi River to the site, where it was held in storage tanks until utilized by the miners.

6. The Barbegal gristmill complex

Just north of the French city of Arles sits the remains of what was once the largest industrial complex in the ancient world. Roman engineers used water provided by aqueducts to both serve the ancient settlement of Arelate and to power a series of cascading mills. Built along the side of a mountain, sixteen mills stood in parallel lines of eight, appearing like steps. The water from the topmost mills, fed by the aqueduct, exhausted to the next, then the next, until after powering its group of eight it was collected in a pool at the base of the mountain. The Berbegal mills began operating in the first century CE, and at their peak produced about 4-5 tons of flour per day.

There is evidence that Roman engineers built similar complexes, at the Janiculum, a hill just outside of Rome, and at Amida in what is now Turkey. The ruins of the Barbegal complex are the most complete, and allow archaeologists and historians, as well as engineers, to gain a better understanding of the impact of ancient Roman engineers on their society. Some suggest the mills of Barbegal, when not needed for grinding flour, were converted to sawmills. The remains of other Roman water-powered mills can be found throughout the area once known as the Roman Empire. Some are even believed to have been used to operate bellows to feed the fires of iron workers in the 2nd century.

5. The undershot waterwheel

The oldest known type of vertically mounted waterwheel is the undershot waterwheel, its use pioneered by the Greeks, and modified for other uses by the Romans. Roman engineers designed and built waterwheels for numerous applications. These included the production of food in gristmills, the operation of power tools such as drills and saws, and the dewatering of underground mines, among many other uses. Roman military engineers experimented with using waterwheels to propel ships, eliminating the oars on their galleys and using the slaves to drive the wheels instead. To date, no such powered vessel has been discovered.

In copper mines in Spain, modern miners discovered the ruins of a cascaded set of waterwheels built and used by Roman engineers to dewater the mine. The sixteen wheels lifted water from the sump of mine approximately 80 feet. Waterwheels to both remove unwanted water and to convert hydraulic to mechanical power were built by Roman engineers throughout Europe and North Africa. For those who believe the ancients lacked power tools their existence in educational. Water-powered tools were used for excavation, cutting and crushing stone, irrigation, sawing wood and marble, and producing food.

4. The segmental arch

The use of the arch to carry loads in construction predates the Romans. Nonetheless, as in other areas, Roman engineers adapted what came before them and improved it to meet their needs. The segmental arch is a case in point. A segmental arch contains a circular arc of less than 180 degrees. When erected with a rise equal to 1/8th of the span over which it soars, the segmental arch resists downward thrust without the need of additional structural support. The first known use of the segmental arch was by Roman engineers, when building the Pont Saint Martin bridge in Italy’s Aosta Valley. The Romans built the bridge circa 25 BCE. Built of stone and concrete, it still stands.

The Romans also extensively used rounded arches, which became known as the Roman arch, and which are visible today in the walls of the Colosseum, the standing aqueducts, and other Roman ruins. Roman engineers placed series of arches side by side, known as arcades, and built arcades on top of one another, building aqueducts, viaducts, and bridges. They also used them to support the roofs of large buildings. Today the Roman engineering method of using the arch to support architectural stresses and loads is visible throughout Europe and North Africa. Both the rounded arch and the segmented arch are still used by construction engineers today.

3. Pontoon bridges

As noted earlier, military necessity is often the impetus for engineering invention. The need for quickly effecting a crossing over a body of water, either to advance against an enemy or flee his wrath, dictated the development of the pontoon bridge. They are a simple enough concept. Floatation devices known as pontoons are lashed together, one by one as they advance across the water, with the most inshore pontoon anchored firmly to the shoreline. Treads, often simply boards, are laid across the pontoons, enabling a transit to the other side. Disassembly is the reverse of assembly. Ancient engineers developed the use of pontoon bridges to a high art, and they were used by the ancient Chinese, Greeks, Persians, Assyrians, and others.

In 480 BCE Xerxes I used pontoon bridges to cross the Hellespont, carrying with him the largest army ever seen up to that time. Julius Caesar relied on them in Gaul during his campaigns. They are an engineering development which has stood the test of time. During the Napoleonic Wars, the American Civil War, and the drive across Europe during World War II, pontoon bridges carried troops, equipment, and even armored columns. Throughout history they have been resorted to both in wartime and in natural disasters as a means of rapidly crossing a water barrier.

2. Roman roads

Roads existed long before the Romans, usually as meandering trails created by the travels of many feet. When a path confronted an obstacle it usually moved off, seeking the means to get around it. Roman engineers changed that forever. The Romans built roads meant to last, and some were built so well they are still in use to this day. Roman engineers designed roads to get where they wanted to go as quickly as possible. Thus, obstacles were overcome, rather than avoided. Rather than go around a swamp, they built a causeway through it if it proved to extensive to be drained. Mountains were tunneled through, forests cleared for the roadbed, and deep ravines and rivers bridged.

The roads themselves, at least the major ones, were engineered to last. Roman engineers built 29 major highways which emanated from Rome; these were fed by smaller localized roads. The Roman highways were paved with stones, with a central high point to facilitate drainage, and with culverts and footpaths running alongside them. By the 2nd century CE over 250,000 miles of paved roads stretched throughout the Roman Empire, an enormous engineering achievement. Thousands of miles of roads today follow the routes built by the Romans, often built directly above their ancient counterparts. In many cases, the pavement set by the Romans is still used by 21st century travelers.

1. Domed public spaces

Today, throughout the world, domes symbolize grandeur and power. They are used in government buildings, churches, and large public spaces, favored because the domed roof allows for wide, open spaces within, with views unobstructed by supporting columns carrying the load of the roof. Roman engineers developed the concept. Using the superior concrete developed by their engineers, Romans built domes which defined, and still define, the shape’s use in architecture. One of the most famous and enduring uses of the concept was the Pantheon, first built during the reign of Augustus, and rebuilt using Roman concrete under Emperor Hadrian, completed circa 126 CE.

The Pantheon’s concrete dome is coffered, containing sunken interior rectangular panels of gradually decreasing size, which add to the impression of height. An oculus (sunlight) is at the peak. The distance from the peak to the floor is the same as the diameter of the dome, meaning a perfect globe could be set within its dimensions. As with all of the engineering achievements of the ancients, it was engineered without the use of mathematical aids such as computers, calculators, or slide rules. The dome itself weighs over 4,300 tons. It remains the world’s largest unreinforced concrete dome. It is also the world’s only ancient dome to still stand without modern day intervention to prevent deterioration and collapse. The Pantheon, now a Catholic Church, is a truly epic tribute to ancient engineering.